Leading Production Before It Existed

June 2021Ford is the second largest U.S manufacturer in the global automobile industry. It has a market cap of $63.83B as of June 04, 2021.

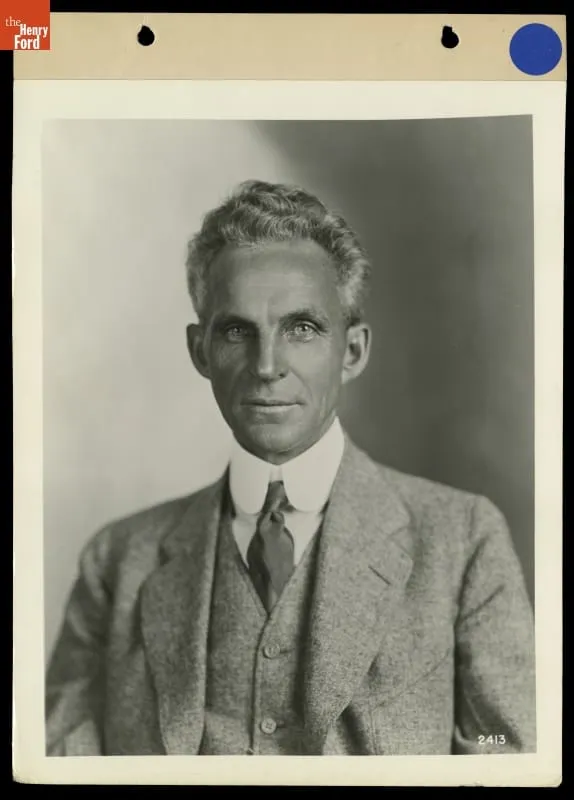

The Revolutionary Optimizer (Source: thehenryford)

Its success depended on the achievement of the incredibly hard task, which can be summarized as “making the car for the common man”.

The main difficulty of this accomplishment had nothing to do with engine technology, welding, coating or aerodynamics.

Henry Ford had to come up with something extraordinary if he were ever to achieve his dream of “producing an automobile that was reasonably priced”.

Born in July 30, 1863, Henry Ford was the eldest of six children in a farmer family living in Detroit, Michigan.

Henry Ford’s Birthplace in Michigan (Source: thehenryford)

He had a curious childhood. Without the interest for agricultural work, Henry was disassembling and installing mechanical tools; looking for gadgets towards making new-to-him experiments in his teenage years.

The opportunity came with the watch his father bought him. Although it was a precious gift, he took it apart and reassembled it without hesitation.

His first successful repair was going to be another watch (which was later donated to the Henry Ford museum) of his schoolmate where he extracted a sliver from the works.

Transition from watch business happened when Ford’s passion for cars became more dominant. He made the decision to continue in automotive industry in 1879.

He built the prototype for his version of “Internal Combustion Engine” in 1896.

Most User Friendly Animation of ICE (Source: NFB)

This engine was going to power the “Quadricycle” model vehicle, three years later.

In 1903, Henry Ford founded Ford Motor Company with 11 investors and a capital of 28 thousand dollars.

Simplification of Ford Logo Through Years-“1903 - 1909 - Present” (Source: designyourway)

After countless failures on different vehicle models, how did Henry Ford finally made it work?

It was his “assembly line” that changed everything.

Winner of the Lemelson-MIT price in 2005, Elwood “Woody” Norris, the inventor with over 100 U.S Patents, explains the assembly line design of Henry Ford as:

“ Not just having an assembly line where the workers moved down the line, but having the line move and the worker stayed in one place and the operation s/he was good at kept popping into sight.”

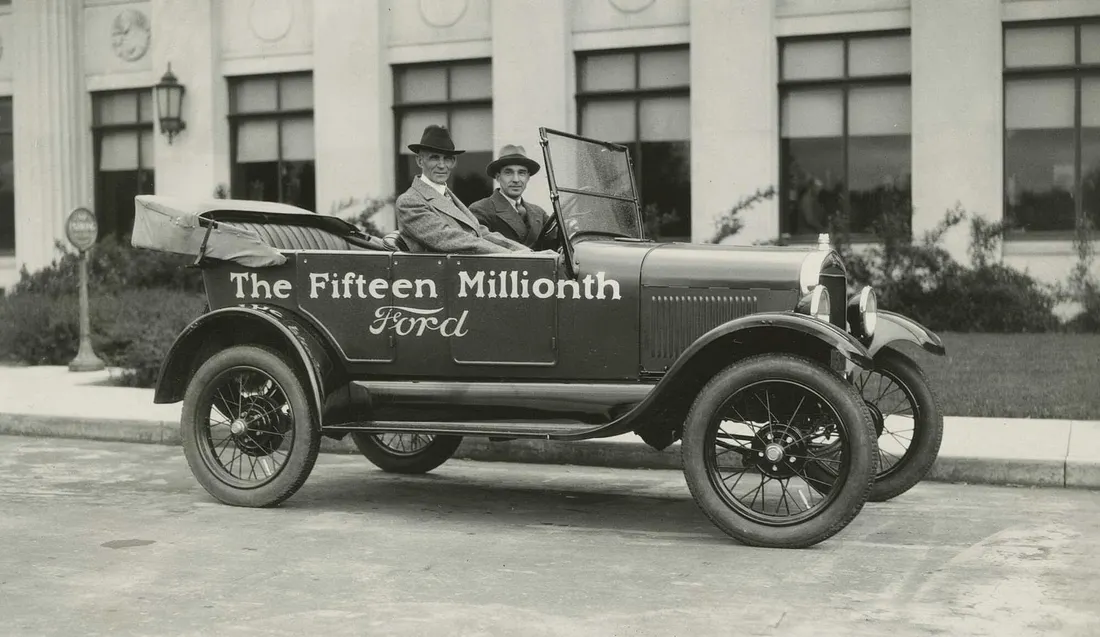

The assembly line significantly decreased the assembly time per vehicle - 12 hours to 93 minutes - and naturally skyrocketed the profit margin.

Ford produced 308,162 cars in 1914, overwhelming all other automobile manufacturers combined.

To this day, this design is the fundamental method of manufacturing in the industry.

Physical products ranging in industries from automobiles, food, toys, furniture etc. pass down assembly lines worldwide before coming to our lives.

Talk About a Milestone (Source: pbs)

I can hear you say, “Hey, where is the two timeless relics that you promised about?”

Well, here they are, with Henry Ford’s quotes.

1) Importance of Self-Talk

Whether you think you can or think you can’t, you’re right.

Henry Ford went bankrupt five times in total. He applied for loans to banks to manufacture cars, but received a negative response each time.

At any point of his lifetime, if he didn’t carry the can-do attitude, none of this would’ve happened.

2) Perspective on Shortcomes

“Failure” is simply the opportunity to begin again, this time more intelligently.

The engine of the first Model-T vehicle he marketed, fell apart during the manufacturing phase. This was an absurdly simple but catastrophic mistake.

Since the design of the engine was Ford’s own, he did not receive support from anyone in repair.

However, he didn’t just stop doing what he set his mind to do, because of a failure.

He always persevered.

Do you think his values align with yours? How could we even improve and adapt his ideas to our present and future?

Always delighted to connect.